How to Classify Centrifuge

Centrifuges are widely used in industrial production. To meet the varying needs of different production processes, there are many types and specifications of centrifuges. They can be classified in the following ways:

1. By Operational Continuity

① Intermittent Operation Centrifuge:

In this type, processes such as feeding, separation, and discharge occur intermittently. Some operations (e.g., feeding and discharge) often require a slow speed or complete stop. Examples include tripod centrifuges and top-suspended centrifuges.

② Continuous Operation Centrifuge:

In this type, all operations are performed continuously (or intermittently) at full-speed rotation. Examples include horizontal scraper discharge centrifuges, piston discharge centrifuges, and screw discharge centrifuges.

2. By Separation Process

① Filtration Centrifuge:

Examples include tripod centrifuges, top-suspended centrifuges, and horizontal scraper discharge centrifuges.

② Sedimentation Centrifuge:

Examples include tripod sedimentation centrifuges, scraper discharge sedimentation centrifuges, and screw discharge centrifuges.

③ Separator:

Examples include tubular separators, chamber separators, and disc separators.

3. By Separation Factor

① Normal-Speed Centrifuge:

Separation factor Fr < 3500, with the range of Fr = 400~1200 being most common. Both filtration and sedimentation types fall under this category. These centrifuges are suitable for suspensions containing larger or medium-sized solid particles and fibrous solids. They feature lower rotational speeds, larger drum diameters, and higher loading capacities.

② High-Speed Centrifuge:

Separation factor Fr = 3500~50000. Typically sedimentation or separation types, these centrifuges are suitable for separating slurry-like materials, fine particles, thin suspensions, and emulsions. They have smaller drum diameters and higher rotational speeds.

③ Ultra-High-Speed Centrifuge:

Separation factor Fr > 50000, primarily for separation applications. These centrifuges are designed for separating highly dispersed emulsions and colloidal solutions that are difficult to separate. Due to their extremely high rotational speeds, the drums are often tubular and elongated.

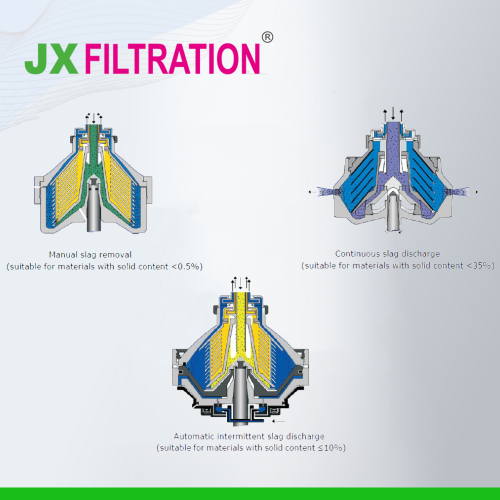

4. By Discharge Method

Centrifuges can also be classified by their discharge methods:

- Manual Discharge

- Mechanical Discharge: Includes scraper discharge, piston discharge, and screw discharge.

- Inertial Discharge: Includes centrifugal discharge, vibrational discharge, and precessional discharge.

Additionally, centrifuges can be categorized based on the spatial orientation of the drum axis, such as vertical or horizontal types.

Summary

While there are many ways to classify centrifuges, no single method can fully capture the structure and operational characteristics of specific centrifuge types. This is due to the complexity of centrifuge designs, making them a typical example of sophisticated chemical machinery.

Any Requirements, Contact Us Now!

Kris

Email/Teams: kris@filtrationchina.com

Mobile/Whatsapp/Wechat: +86 18980776200