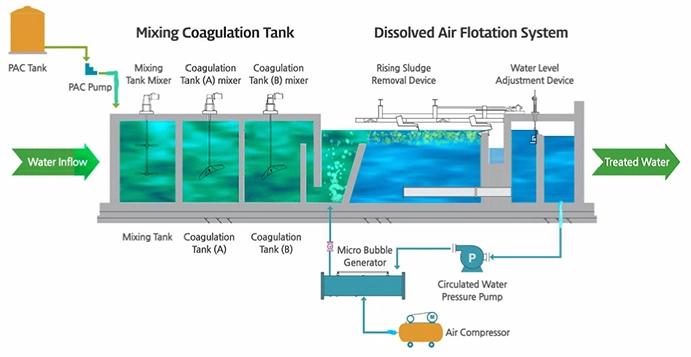

Dissolved Air Flotation

Dissolved Air Flotation is a widely-used solid-liquid separation equipment in wastewater treatment industry. It can effectively remove the suspensions, oils, and adhesives in the wastewater, one of the key equipment in the early processing.

Working principle

The dissolving air tank can produce dissolving gas which later be released to the water waiting to be treated through the release device. It will form tiny bubbles of 20-40um and those tiny bubbles will combine with suspended solids in the waste water to make the proportion of these suspended solids smaller than water and gradually float to the surface to form scums. With a scraper system on the surface, these scums will be scraped into the sludge pool while the water will enter the clean pond from the lower part of the overflow trough.

Features

- The dissolved air pump sucks in while absorbing water, the pump is pressurized and mixed with high gas-liquid dissolving efficiency and the fine bubbles are less than or equal to 30um.

- Low pressure operation, the dissolved gas efficiency is as high as 99%, and the release rate is as high as 99%.

- The efficient adsorption of microbubbles and suspended particles improves the removal effect of SS.

- The dissolving efficiency of dissolved air water is 80-100%, which is 3 times higher than that of traditional dissolved air flotation.

- The pressure capacity curve is flat, easy to realize automatic control, easy to operate and maintain with low noise.

Application

Slaughtering, starch, pharmaceuticals, papermaking, printing and dyeing, leather and tannery, petrochemical industry, domestic wastewater, etc.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160