Vibratory Separator

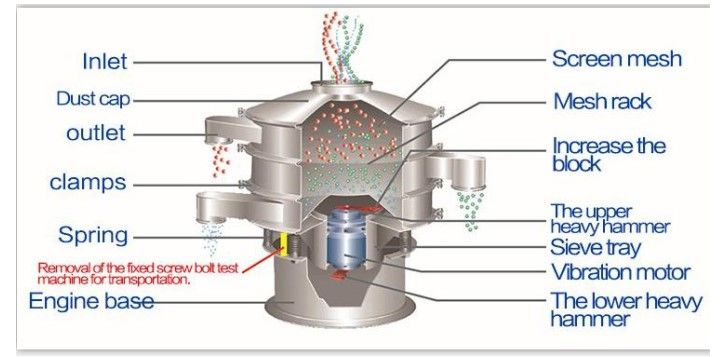

The Vibratory Separator generally consists of a screen cover (usually provided with a feeding interface), a screen frame (built-in screen components, which are formed by coil welding), a driving device (usually a vertical vibration motor), and a vibration isolation device (a set of It is composed of several parts such as support spring), base, etc. Among them, the screen cover and screen frame are vibrating parts, and the other parts are non-vibrating parts. In addition, the base also has a supporting function.

Working principle

The Vibratory Separator, also known as the rotary vibrating screen, uses a vertical vibrating motor as the excitation source. The upper and lower ends of the vibrating motor are installed with eccentric weights, which convert the rotating motion of the vibrating motor into horizontal, vertical and inclined. Three-dimensional motion, and then transfer this motion to the screen surface. Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.

Basic functions

Screening: Screening is to divide particles and powders into particle segments of different sizes. It can continuously sort out 2-6 fractions and control a narrow particle size range.

Screening out impurities: high-precision screens can quickly remove large or small particles with low percentages in the process of high-flow material processing.

Solid-liquid separation: Three-dimensional vibration and high-precision screen filtration can quickly remove insoluble solid substances in various slurries.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160