What is Decanter Centrifuge

Horizontal spiral discharge sedimentation centrifuge (referred to as decanter centrifuge) is a device that uses the principle of centrifugal sedimentation to separate suspensions. For the solid phase particle equivalent diameter = 3um, weight concentration ratio: 10% or volume concentration ratio = 70%, liquid-solid specific gravity difference: 0.05g / cm3 of various suspensions are suitable for the use of this type of centrifuge for liquid-solid separation or particle classification.

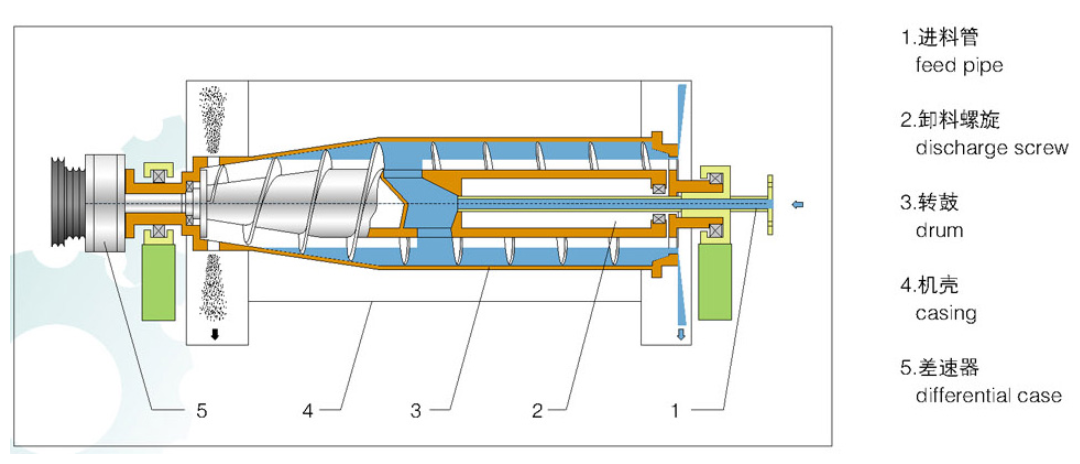

The non-porous bowl is equipped with a visual discharge spiral, and the two rotate in the same direction at high speed, but also have a certain speed difference, which is generated by the transmission system and the differential. The suspension enters the inner chamber of the feed spiral from the feed tube.

After acceleration, it enters the drum. Under the action of centrifugal force, the dense solid phase particles settle to the inner wall of the bowl. The sediment ring layer is formed, and the discharge spiral is continuously pushed to the small end of the drum and discharged out of the bowl, and the clear liquid is continuously discharged from the overflow port at the big end of the bowl, thereby realizing the solid-liquid separation of the suspension.

Technical Features

The Decanter Centrifuge can continuously feed, separate and unload at full speed. It has the characteristics of compact structure, easy to seal, smooth operation, small noise, large processing capacity, low energy consumption and high degree of automation, small labor intensity, convenient operation and maintenance, and wide range of adaptation.

Application

It is suitable for solid phase dehydration, liquid phase clarification separation and liquid, liquid and solid phase separation and particle classification of various suspensions with solid phase particle size 0.005~15mm, concentration of 1-40% and temperature ≤ 100 °C.

It is especially suitable for the separation of suspensions with difficulties in filter cloth regeneration and large changes in concentration and particles. Such as polyvinyl chloride resin, ammonium sulfite, barium carbonate, strontium sulfate, Lide powder, starch, diatomaceous earth, gypsum, bauxite, soybean protein, peanut protein, fruit juice, beverages, vegetable oil, citric acid, blood powder, titanium dioxide, kaolin drilling mud and other processing and refined coal dehydration, fly coal dehydration, waste oil lees waste liquid, mineral grading treatment, municipal sewage treatment and power plant sludge printing and dyeing sludge, papermaking sludge and other industrial wastewater treatment areas.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160