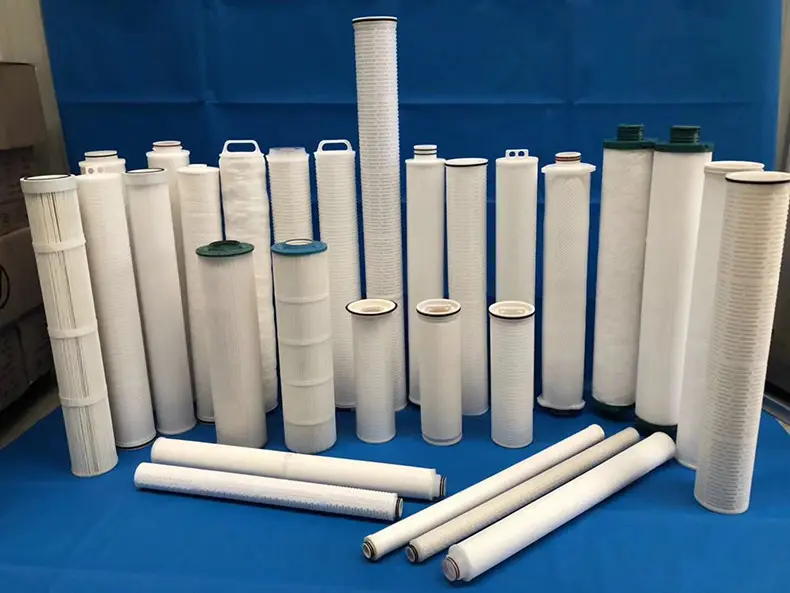

Cartridge Filter

Cartridge filter consists of two parts: filter housing and filter element. Mainly removes fine particles from water. The built-in filter element is made of PP melt-blown filter element, wire wound filter element, pleated filter element, absorbent cotton filter element, activated carbon filter element, etc.

Loading filter elements of different materials and different precisions can effectively remove all kinds of tiny impurities based on the pore size of the filter element. The filter element consists of various types of filter elements such as meltblown core, wire wound core, folded core and sintered core.

Working principle

The filtered liquid is pressed into the filter inlet, and filtered into a clear liquid through the filter element through the filter layer from the outside to the inside, and then discharged through the outlet. Impurities are trapped in the deep layer and surface of the filter element, so that the liquid can be filtered.

Features

The structure and size of the filter element of the liquid cartridge filter depend on the design flow rate and the characteristics of the medium for filtering the liquid. It is not only small in size, low in cost, large in flow rate, but also convenient for maintenance, core replacement and assembly. The filtration precision is 0.005-20um and the flow rate is 5-200m3/h. Products of different sizes can also be made according to user needs.

Application

It has been widely used in water, oil, ink and other liquid purification and solid-liquid separation in machinery, metallurgy, chemical industry, textile, printing and dyeing, electroplating, medicine, food and other industries.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160