What is Direct Discharge Vibrating Screen

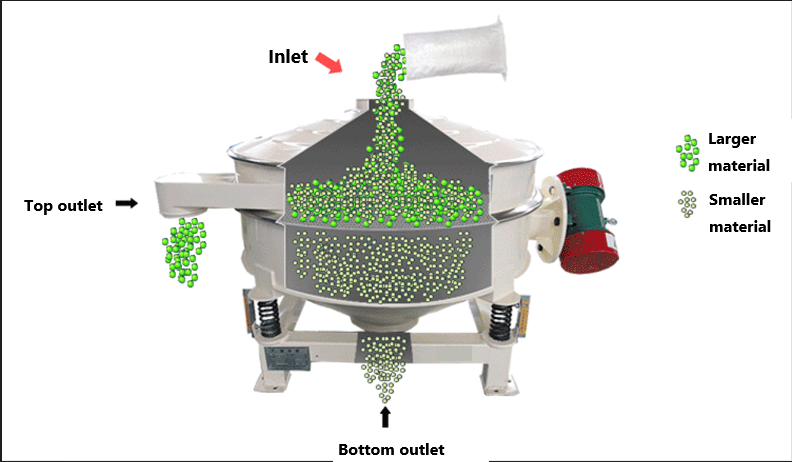

Direct discharge vibrating screen uses a single horizontal vibration motor as the excitation source. The vibration motor is placed on one side of the body. After the material enters the equipment, the force of the vibration source makes an elliptical motion trajectory on the screen surface. At the same time as the rapid and reciprocating action of passing the mesh is completed, the vibration force can continuously peel, disperse and reorganize the material, so that the material can pass through the mesh quickly. If the material that cannot pass through the mesh is discharged from the discharge port on the screen according to the movement trajectory of the equipment, the screening operation process is completed.

The Direct Discharge Vibrating Screen is mainly for the screening of flour powder materials, and the maximum mesh number of flour powder materials is 140 mesh, so the highest sieving mesh of the vertical sieve is 140 mesh; and the three-dimensional rotary vibrating screen is equipped with mesh cleaning device, so the material below 500 mesh can be screened at most.

Product Features

- The inlet and outlet are designed in the same vertical direction, the large flow outlet at the bottom enables the material to be discharged directly, the discharge speed is fast, and the output is 2-5 times that of the ordinary rotary screen

- Simple structure, easy to maintain.

- It can be used directly in series in the pipeline to remove impurities in the pipeline without manual operation and avoid secondary pollution to materials.

- The sealing effect of the equipment is good, and it is difficult for dust to escape.

- Automatic discharge, suitable for assembly line work.

- Because the motor is designed outside the equipment, the height of the equipment is reduced and the space is effectively used.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160